Page 1 of 2

Camhead - Gear Linkage Lubrication

Posted: Wed Dec 07, 2022 9:51 pm

by David.

There has been some discussion in the "Winter Maintenance" thread about gear linkage lubrication. Found a thread on R1200GS.INFO which suggests that BMW now recommends to remove grease from the shift lever.

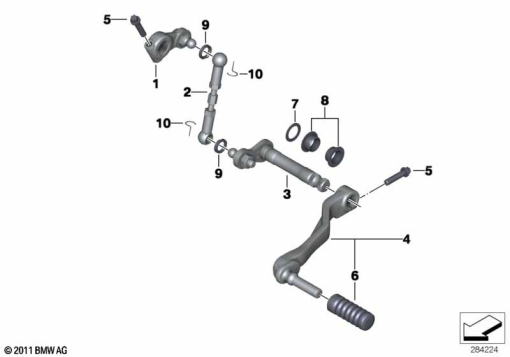

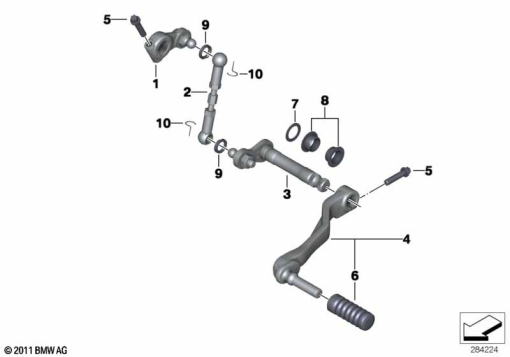

https://www.r1200gs.info/threads/update ... %20bearing. Although a different set up, there is a PTFE bush on which the shift lever pivots. On my Camhead, the bushes also look like PTFE, this would suggest that grease should not be applied. Whilst lubricating the cup & ball joints is probably good practice. Any comments would be much appreciated before I reassemble the gear linkage.

This is what the Camhead bush (#8) looks like, is it PTFE.

"A PTFE-bearing is maintenance free; do not lubricate the bearing."

"A PTFE-bearing is maintenance free; do not lubricate the bearing."

Re: Camhead - Gear Linkage Lubrication

Posted: Wed Dec 07, 2022 10:45 pm

by Stu

I am led to believe that ptfe can swell when exposed to certain lubricants

So probably best to do as it says and not lubricate it

I would give everything a good clean too

Re: Camhead - Gear Linkage Lubrication

Posted: Wed Dec 07, 2022 10:49 pm

by David.

Any recommendations on the best type of grease for the cup & ball joints, (waterproof would probably be a good start). There appeared to be some evidence of a white type grease on the lower joint when dismantled. Part #9 is a plastic (foam type) washer, this is possibly there to help keep water and dirt out of the joint. I'm pretty sure, (need to check), that this was missing from the upper joint which was in poorer condition and slightly corroded. Think I'll order a couple of new washers for reassembly.

Re: Camhead - Gear Linkage Lubrication

Posted: Thu Dec 08, 2022 6:33 am

by Dreadnought

Personally, I tend to ensure that stuff like this has a good coat of ACF50 and / or FS365, it's not like they require heavy duty lubrication, and this method has never caused me any issues over the 10 or so years I've been using it.

Re: Camhead - Gear Linkage Lubrication

Posted: Thu Dec 08, 2022 8:40 am

by Our Gee

Some of our more established members may recall that I have been advocating an annual "Service" of the Gear Linkage for years now with absolutely no interest shown. This latest discussion is welcome and indeed seems to be generating a healthy interest. With regard to the application of Grease to the linkage Shaft support Bushes my own experience gained over about 15 years of RT ownership including one Hexhead and two Twincams, all of which where regularly subjected to grease being applied to the said Shaft Bushes has been nothing but positive. As far as I know my Shaft Bushes have never disintegrated and the Shift Action has been good. Although I have re-placed these Bushes in one of my bikes this was not really necessary and only done during winter boredom !!. As for sourcing the "Correct" type of Grease to be used in a location which, in the vast majority of Bikes will have never seen the light of day since factory assembly I wouldn't worry. Anything will be better than nothing.

Re: Camhead - Gear Linkage Lubrication

Posted: Thu Dec 08, 2022 8:45 am

by David.

I used to get my Camhead treated with ACF-50. Even though it was not used from 1st Nov. to 31st March you do get moisture in the garage. I found that ACF-50 just attracted dirt which stuck to the bike. The gear linkage was grubby and it would now appear that the PTFE bushes should not be lubricated, especially with an oil based lubricant. ACF-50 will not lubricate the cup & ball joints which required attention.

Re: Camhead - Gear Linkage Lubrication

Posted: Thu Dec 08, 2022 9:19 am

by Dreadnought

David. wrote: ↑Thu Dec 08, 2022 8:45 am

I used to get my Camhead treated with ACF-50. Even though it was not used from 1st Nov. to 31st March you do get moisture in the garage. I found that ACF-50 just attracted dirt which stuck to the bike. The gear linkage was grubby and it would now appear that the PTFE bushes should not be lubricated, especially with an oil based lubricant. ACF-50 will not lubricate the cup & ball joints which required attention.

You're missing the point of using ACF50, it's to prevent corrosion build up and thus eliminate the need for lubrication, i.e. a barrier, yes dirt builds up but hey you can always clean your bike a bit more. FS365 does the same thing, it's a barrier not a lubricant

Re: Camhead - Gear Linkage Lubrication

Posted: Thu Dec 08, 2022 9:43 am

by David.

David. wrote: ↑Wed Dec 07, 2022 10:49 pmPart #9 is a plastic (foam type) washer, this is possibly there to help keep water and dirt out of the joint. I'm pretty sure, (need to check), that this was missing from the upper joint which was in poorer condition and slightly corroded. Think I'll order a couple of new washers for reassembly.

Checked this morning and I wasn't seeing things. There is definitely not a plastic/foam type washer on the top (gearbox) cup & ball joint. This is the one which was slightly rusty. Whereas on the lower (shift lever) joint there was evidence of some assembly grease. Shows that the washer must be there for a reason.

Have ordered two replacement washers (£1.50 each) from my local BMW car dealer rather than a 70 miles round trip to a Motorrad dealer or pay postage. They will be available for collection tomorrow.

Re: Camhead - Gear Linkage Lubrication

Posted: Thu Dec 08, 2022 10:33 am

by Stu

I'm a firm believer in keeping on top of things like this and a silicon grease or lithium grease is what I would use and I would look at stripping, cleaning and a re grease once a year

Re: Camhead - Gear Linkage Lubrication

Posted: Thu Dec 08, 2022 10:37 am

by David.

My local BMW DIY mechanic has both recommended the use of and supplied a quantity of Lucas Red 'N' Tacky Grease for the cup & ball joints.

https://www.lucasoil.co.uk/products/gre ... cky-grease

Re: Camhead - Gear Linkage Lubrication

Posted: Thu Dec 08, 2022 10:48 am

by David.

David. wrote: ↑Thu Dec 08, 2022 8:45 amIt would now appear that the PTFE bushes should not be lubricated.

https://www.viiplus.com/faq-items/steel ... E%E2%80%9D

"The PTFE-based sliding surface permits smooth, low-friction operation without lubrication."

Re: Camhead - Gear Linkage Lubrication

Posted: Thu Dec 08, 2022 8:59 pm

by simbo

50k miles on my RT ridden all year round, I've never touched the gear linkage and everything works fine

I can sense another warranty claim coming on from David

Re: Camhead - Gear Linkage Lubrication

Posted: Thu Dec 08, 2022 9:16 pm

by David.

Funnily enough, when the bike was collected for servicing last Monday, initially, 1st gear selection proved difficult. The bike had been stood for 6 weeks. Best get the dealer to change the gearbox oil when it is due next year for the upcoming warranty claim. When the bike was returned there was no problem with gear selection, just goes to show, they are better used than stood.

P.S. Part of the service was to have the F&R brake fluid changed, therefore, the callipers are covered under warranty.

Re: Camhead - Gear Linkage Lubrication

Posted: Thu Dec 08, 2022 9:28 pm

by simbo

David. wrote: ↑Thu Dec 08, 2022 9:16 pm

When the bike was returned there was no problem with gear selection, just goes to show, they are better used than stood.

Very much so

Re: Camhead - Gear Linkage Lubrication

Posted: Sun Dec 11, 2022 12:02 am

by bicyclenut

I've lubricated mine regularly since the weld on the shifter mount cracked with 150 miles to get home from a 1000 mile IBA ride. Bike had about 80K on it at the time it happened. It became hard to get back into 1st gear but I made it home. Can't be sure if it was due to lack of lubrication or binding of the linkage or maybe it was just a flaw in weld or corrosion. I don't recall the shifter feeling unusual, but it may have been binding a bit as it seem to require a bit more effort, but that could have been as it was breaking and I hadn't noticed it yet.

Luckily I was able to find someone to weld it and it held up and when I had the rear subframe off to do the clutch he reinforced it and was able to get welds on all sides. I now regularly lubricate it with grease with teflon and have taken apart the joints and cleaned them as well as replaced the nylon parts. It seems to move much better when kept lubricated and clean.